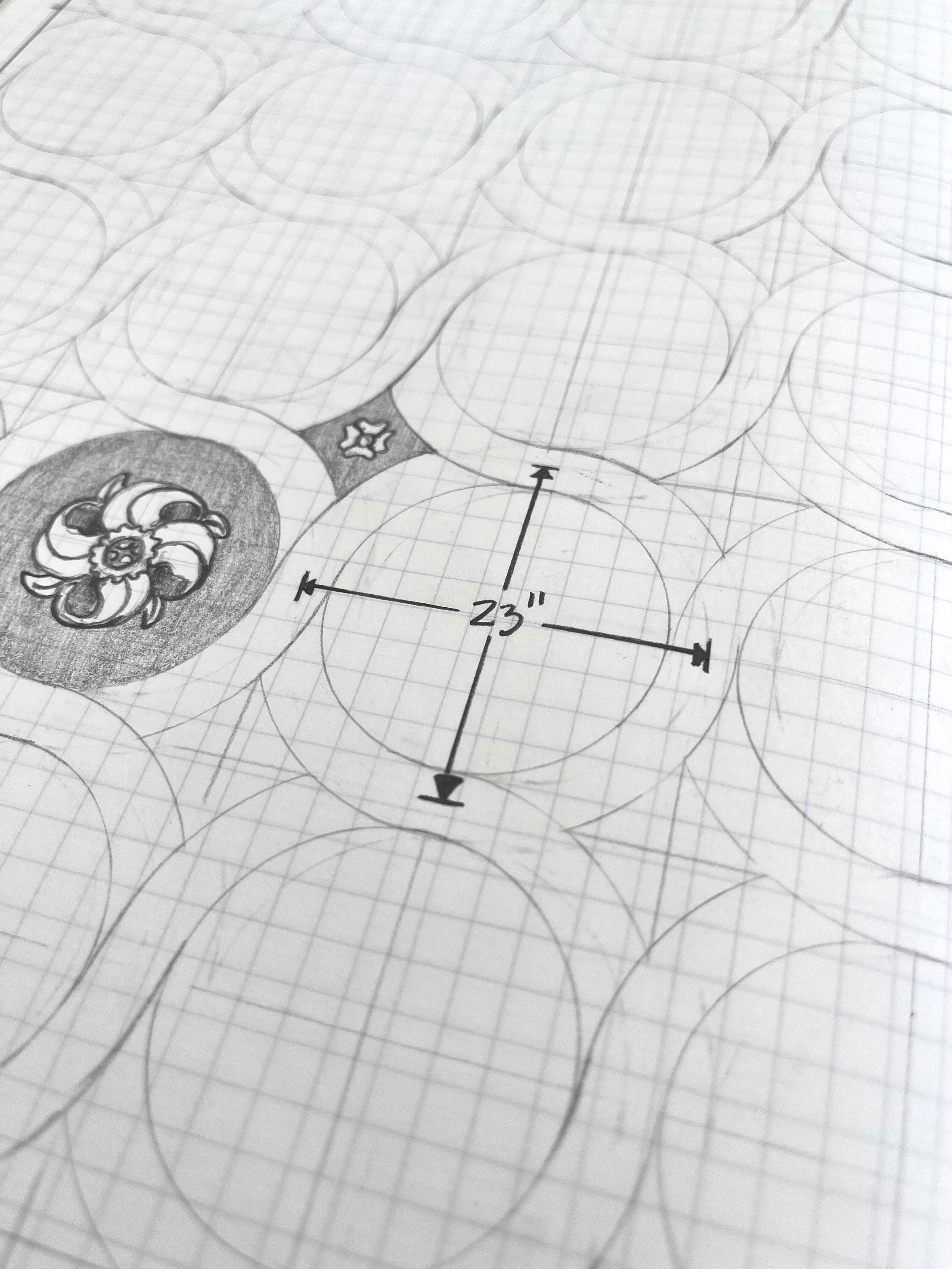

It starts with an idea, sketches, and math

The start of a floorcloth is like a puzzle. Design possibilities are endless and limited only by imagination. From historical designs such as greek mosaics, the fluid lines of Art Nouveau, patterns from wallpaper or carpets, solid colors, or something entirely unique. Some clients know exactly what they want and others want some help, which we are happy to give. Then we need to make the design work within the limitations of the space. Making sure all of the measurements are correct before paint hits the canvas. We sometimes have to work around stairs or other architectural elements so having a visual outline before any work is done is crucial. In many cases, we will come to the client and take measurements. During all of this, colors are chosen. If needed, we will provide a sample.

Not your normal canvas stretching and priming

The most physical part of making a floorcloth is stretching #10 duck canvas around a 2x4 frame. Duck canvas was originally designed for sailcloths. It is heavier and more durable than traditional canvas. After a long vacuuming it is time to roll on a coat of aqua lock primer and 3 coats of Benjamin Moore Low Lustre exterior white. On each side of the canvas. This not only protects the canvas but creates a bond within the weave to keep the floorcloth flat yet pliable. The combination of stretched duck canvas and paint keeps the floorcloth flat. There is no edge or corner curling to make it a trip hazard. It is then lightly sanded and a base color applied. After that, the floorcloth is ready to be measured and cut to size. The photo is a 9’ x 28’ canvas.

Paint, tape, paint, tape, paint

Now the floorcloth starts to become something. Whether it’s a 5 step marbling process, solid color, or complicated pattern. We only use Benjamin Moore exterior Moore Glo Soft Gloss paints. We can get Farrow and Ball colors with this paint. The photo is of an 18’ x 28’ floorcloth.

Topcoating

After the paint is dry and the floorcloth washed and vacuumed, it’s time for topcoating. A lot of prep work goes into making sure it is applied smooth and clean. Multiple coats of Benjamin Moore Low Lustre Stays Clear is brushed on. Not sprayed. The canvas texture will cause air bubbles if sprayed. Stays Clear is a non yellowing polyurethane. We have found this product to be best for high traffic, and it does not make the floorcloth stiffen and crack over time. The photo is of a very wet topcoat. It will dry to a crystal clear finish. We can wax the floorcloth as well. That adds an extra layer of protection. Wax can make them a bit slippery to walk on with socks. Depending on where the floorcloth is, we recommend waxing every 6 months.